As a non-contact marking equipment, inkjet equipment can provide character printing. In the process of inkjet coding, sometimes there will be the problem of unclear inkjet characters, which will affect the reputation and use of products. Therefore, manufacturers should test the inkjet codes on product packaging before leaving the factory.

In recent years, the automatic recognition technology of inkjet character image has been applied to a certain extent. However, due to the influence of the font, color, background, font inclination and other interference factors in the fast movement of the printing character, it often causes the recognition error or unrecognizable situation.

The traditional detection method is to use manual detection, but the manual detection method will often fail to detect. At the same time, as the speed of production increases, the human eye can no longer keep up with the speed of the product. Yogurt production line application of OCR character detection system, enterprises can efficiently complete the product packaging code detection, but also can correctly read the product packaging information, so as to strictly check the product quality.

Test contents:

Yogurt manufacturers need to carry out online detection of the spray code content on the yogurt bottle cap before leaving the factory, and eliminate products with missing spray code, missing spray code or wrong spray code to ensure the accuracy of product spray code.

Difficulty of detection:

Yogurt bottle cap spray code is mostly dot matrix spray code, and dot matrix spray code character font size, the amount of ink and the influence of light changes, so that it is difficult to accurately locate and identify dot matrix spray code characters.

Solution:

The OCR character detection system converts characters into image signals through industrial cameras and transmits them to image software processing systems, which convert them into digital signals according to information such as pixel distribution and brightness. The image software processing system checks the string with the decision string, provides the character matching detection information and statistical data in real time, realizes the automatic identification of production detection information, avoids the occurrence of misrecording, missing recording and other problems.

Work flow:

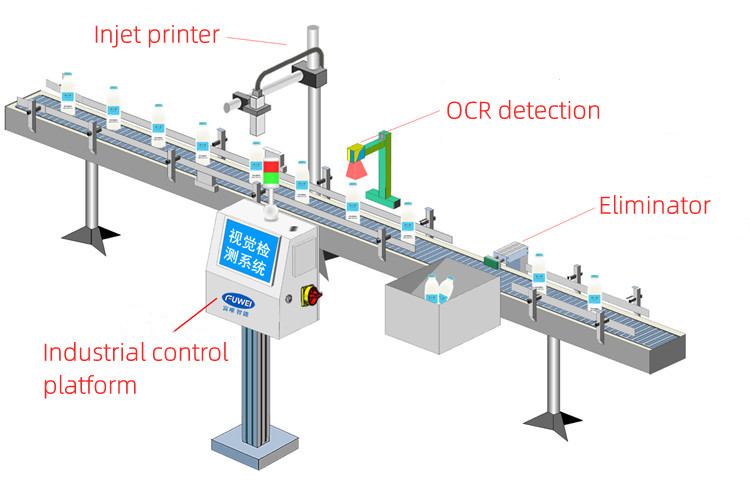

1. Install OCR character visual detection system on yogurt production line;

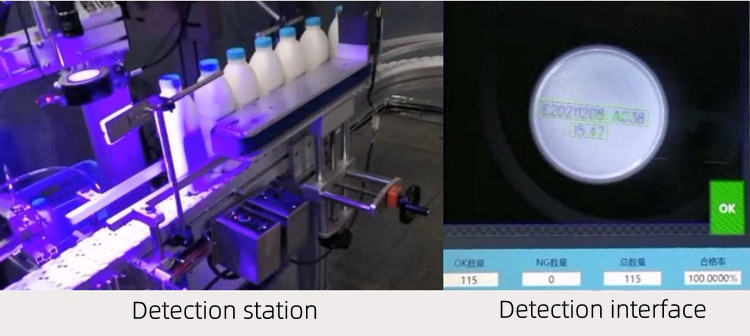

2. When the yogurt bottle flows into the visual detection station, the picture of the bottle taken by the machine vision sensor is sent to the system, and the system extracts and analyzes the picture taken and compares it with the set to know whether the characters of the spray code of the yogurt bottle cap are missing or fuzzy;

3. When detecting the missing and fuzzy characters of the spray code of the yogurt bottle cap, the system will send NG signal to the removal device to give removal processing and alarm.

System flow chart

Fuwei intelligent OCR character detection system can confirm, identify and determine the characters printed on the workpiece or products, and perfectly achieve fast and accurate recognition of the packaging characters of food production lines, the recognition speed can reach 18,000 bottles/hour.

Reliable OCR character detection equipment has become one of the effective means for enterprises to ensure food safety and quality, improve safety and compliance. On the high-speed packaging production line, machine vision detection system plays an indispensable role. The application of machine vision technology not only gradually replaces the manual to complete the heavy and boring work, but also its reliability and low cost occupy a great advantage, with a very broad market prospect.