With the rapid development of industrial manufacturing technology, the automation and intelligence of production factories in various industries are getting higher and higher. Robotic arms replace manual production automation to complete most of the production automation links, which greatly improves production efficiency and productivity, while composite robots realize the automatic docking and circulation of each link, and truly realize unmanned production.

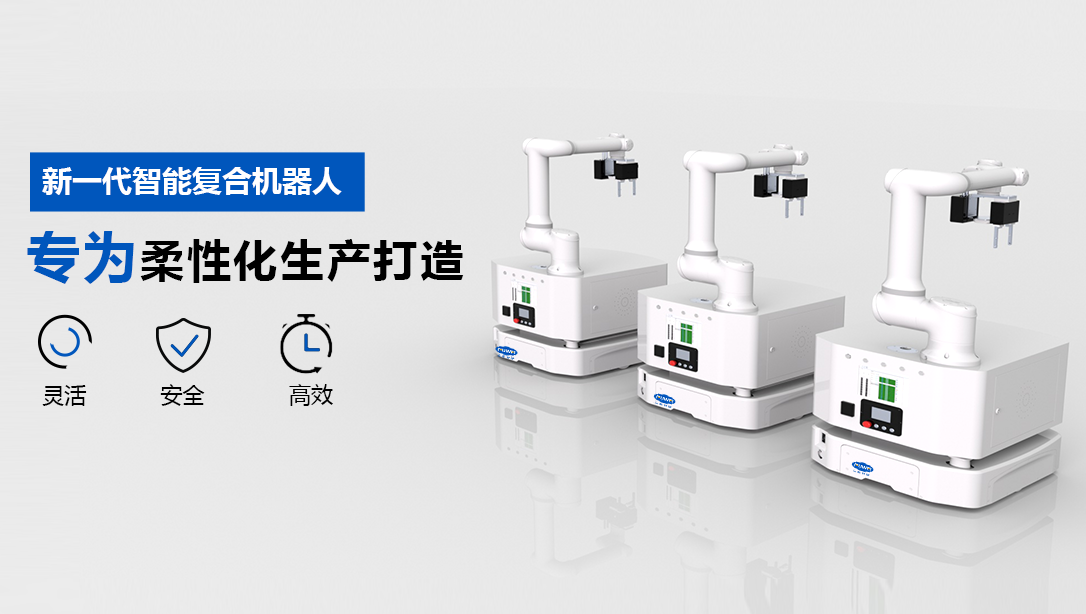

The intelligent composite robot has the dual functions of AMR(mobile robot) and collaborative robot, and combines the large range of mobile performance of AMR and the precise operation of multi-degree of freedom cooperative robot arm, greatly expanding the application range. Especially suitable for various scenes of handling, loading and unloading, inspection and other scenes, while the modular accessories make it possible to use one machine.

Product features:

1, automatic path planning, no need for track;

2, ForwardControl software, to achieve integrated control, multi-task planning;

3, man-machine collaboration, safe and reliable;

4, visual positioning high-precision operation ability, up to 0.2mm;

5, simple deployment, visual management;

6, automatic charging (can be set 10%-100%);

7, double laser ultra-stable navigation (accuracy 5mm);

8, battery upgrade iron phosphate carp, safe and reliable, ultra-long duration ≤12h;

9, automatic sleep function, equipment idle sleep (time can be set at will).

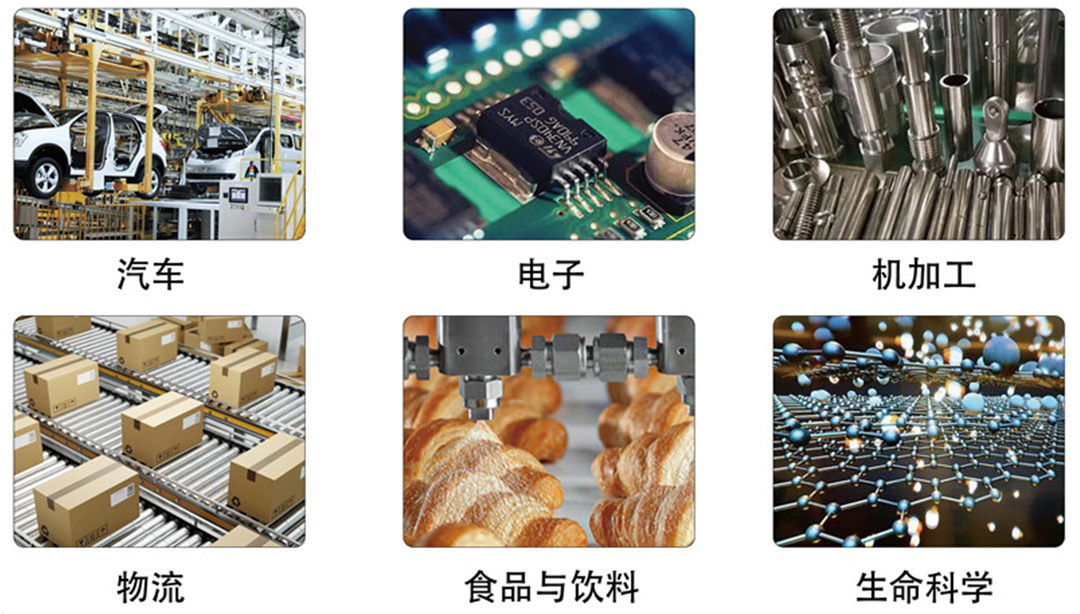

Industry application:

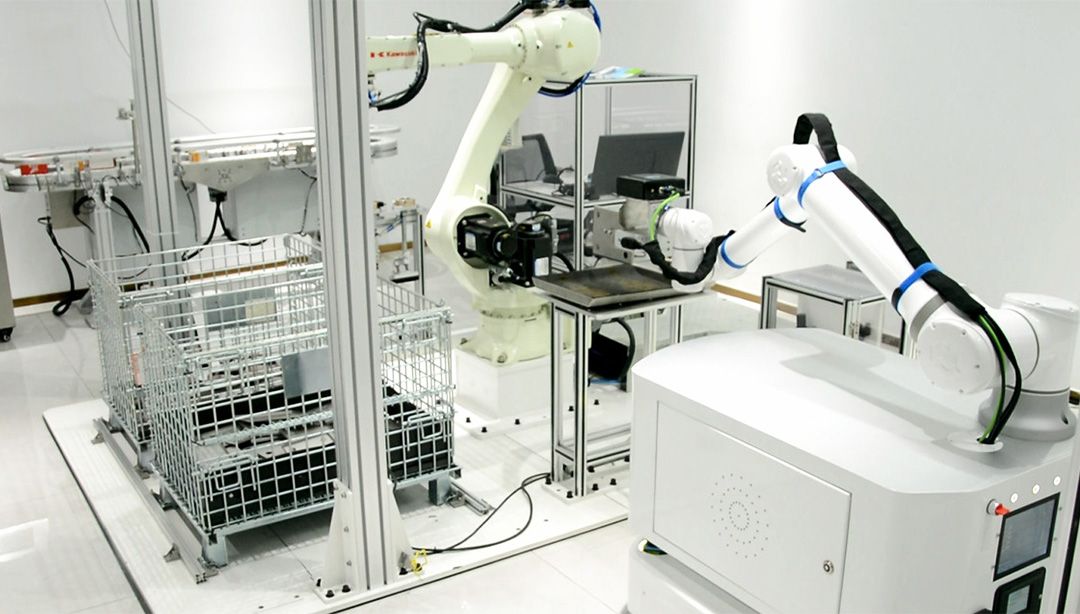

Application Case:

Composite robot automatic loading frame

It can realize the automatic loading and transfer of materials, reduce manual operation and error rate, improve production efficiency and reduce costs.

Composite robot automatic feeding

Materials can be transferred from storage areas or other sources to production line equipment, improving feeding efficiency and accuracy, and reducing human resource consumption.

Composite robot vision high-precision positioning

Through visual technology to identify and position the object, achieve accurate placement and detection, improve the precision, efficiency and product quality of the production line.

Intelligent composite robot is a new type of industrial robot with broad application prospects, which can cooperate to complete more complex tasks and inject new impetus and vitality into the development of industrial automation. With the continuous development of artificial intelligence and machine learning technology, the intelligent and autonomous level of composite robots will continue to improve, and it will become the main force of industrial automation in the future, bringing more convenience and benefits to humans.