With the transformation and upgrading of industry 4.0 and enterprise digital intelligence, machine vision, as one of the important means to realize industrial automation and intelligence, is widely used in industrial production. Domestic vision technology has been increasingly mature, as a typical technology of industrial intelligent camera and machine vision system is also gradually developing.

The difference between industrial intelligent camera and machine vision system

Industrial intelligent camera is not a simple camera, but a highly integrated micro machine vision system. Machine vision system is equivalent to the eyes of the machine, mainly through optical devices and non-contact sensors to receive and process the image of real objects, in order to obtain the required information or used to control the movement of the robot device. They differ in size, hardware composition, software and so on.

1. Volume

Industrial intelligent camera is small and delicate, save installation space, a camera, without the need for IPC, it will be the image acquisition, processing, communication functions integrated in one, easy to install, load, unload and move.

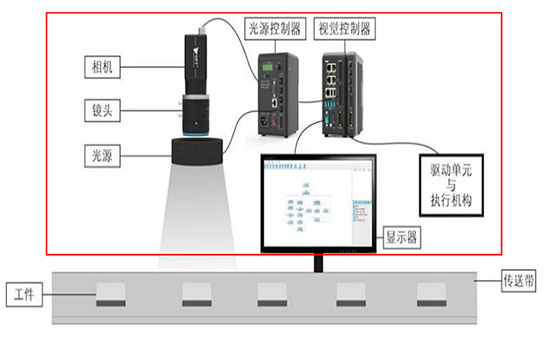

The machine vision system is generally larger and more complex than industrial intelligent cameras. It is composed of light source, CCD or CMOS camera, image acquisition card, image processing software and so on.

2. Hardware

Industrial intelligent camera consists of image acquisition unit, image processing unit, image processing software and network communication device, etc., has formed a standardized product, high efficiency and stability. However, due to the fixed hardware circuit, it is difficult to change, unable to deploy different types of products, lack of flexibility.

The machine vision system is mainly composed of camera, acquisition/processing card and industrial computer. Users need to choose different functions according to the needs, so the design is more flexible.

3. Software

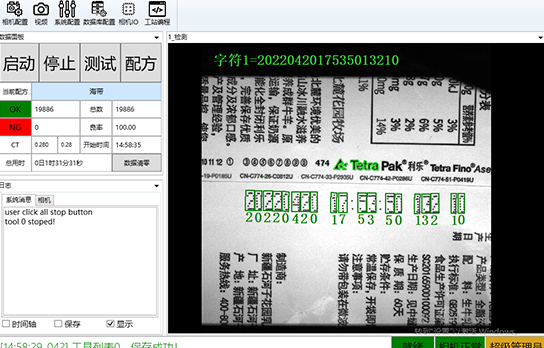

Industrial intelligent camera is a more general machine vision product, its software function has a certain versatility, because the intelligent camera has solidified mature machine vision algorithm, users do not need to program, can achieve detection, barcode recognition, shape matching, area detection and other functions.

The software of machine vision system can generally be customized and developed. Suitable algorithms can be developed according to the specific application of their own products, and customized and developed according to customer needs. Machine vision software because of the different level of software development and hardware support, different manufacturers research and development of the same kind of application system differences are also large.

Industrial intelligent camera and machine vision system itself will have certain limitations and obstacles. Industrial intelligent cameras have limited computing power and poor software flexibility, while machine vision systems are non-standardized products, which are easily affected by differences in software and hardware levels.

Industry 4.0 cannot be separated from intelligent manufacturing, which cannot be separated from machine vision. With the continuous innovation and upgrading of domestic vision-related enterprise technology, industrial intelligent camera and machine vision system have been greater development, but also for the whole machine vision industry has brought broader market space.