In the future, robots can gradually replace workers in production operations in factories, which can not only save a lot of costs, but also obtain qualitative leaps in production accuracy and production efficiency. Unmanned chemical plants in the future are not impossible. With the further development of 'Made in China 2025', robot visual guidance technology is becoming more and more important.

Automation is the foundation of modern industry. The global industrial robot market, valued at $37.875 billion in 2016, is expected to reach $70.715 billion by 2023, growing at a CAGR of 9.4% from 2017 to 2023. As manufacturing moves to Industry 4.0, industries are actively seeking more automation opportunities and technology enhancements.

At present, the demand for industrial robots mainly comes from the manufacturing industry, such as welding, painting, parts handling, etc., in the automobile and motor industries. But with the rise of the Internet of Things and artificial intelligence technology, especially machine vision, robots can do more delicate work, leading to a promising market outside the manufacturing industry of 'visual robots'.

Machine vision is the first step to achieve intelligence

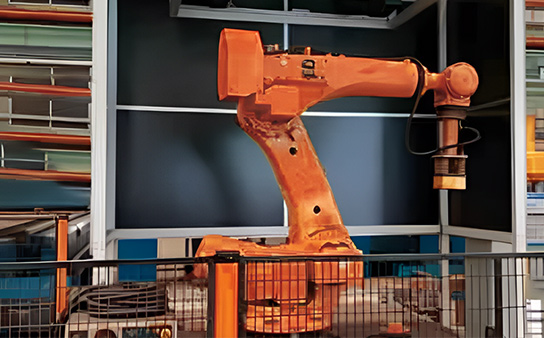

With the continuous upgrading and transformation of the manufacturing industry, the robot's eyes are an important key to the intelligent machinery industry. Don't look down on every movement of the robot, for human is very simple action, in fact, it is not easy for the robot. There are many aspects behind each robot action, including image recognition, algorithm, data, information processing, machine learning, instruction execution, etc., and how to integrate these to make the robot complete the action accurately and smoothly is a big challenge.

In other words, it takes a combination of optics, software, robot controls, and mechanisms to create a complete robot vision system that can tell the robot how to accurately pick up objects in a clutter or perform other tasks.

Visual guidance makes efficiency even higher

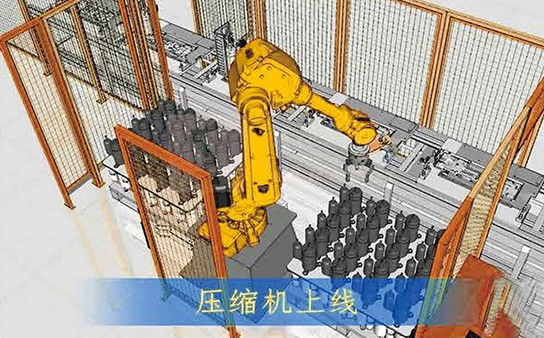

Traditionally, in industry, robotic arms have only been able to do simple repetitive motions, and then machine vision. Although the robot has eyes is not 'omnipotent', but without eyes is 'absolutely cannot'. For a manufacturer who wants to automate the process, the first thing to do is to make the machine recognize different materials.

When the current industry uses machine vision technology for intelligent analysis, most of the calculation is still carried out through 2D images. The advantage of 2D is that the camera lens can obtain the simulated plane color elements, but the disadvantage is that it can not obtain the spatial depth distance and can not carry out more accurate analysis and application. In addition, the factory environment is difficult to predict, often encounter some parts overlap or lighting, reflection and shadow and other factors, affecting the quality of the factory when 'picking' materials.

One of the core aspects of 'Made in China 2025' is robot intelligence. Vision technology represents the eyes and brains of machines, and machine vision will make robots intelligent.

Fuwei Intelligent provides standard solutions for visual guidance, adopts self-developed and efficient visual algorithms, provides one-stop visual solutions, hardware and software and peripheral equipment design, and has industry-leading random grab hardware and software system. The 'AI +2D/ 3D vision + robot' method is used to realize the robot vision guidance technology, which can help the robot/manipulator industry realize intelligent functions, so as to meet the requirements of 'Made in China 2025'.