In the past decade, laser welding has been favored, but the market demand did not increase significantly, until the explosive growth of domestic new energy vehicles in recent years, the expansion of power battery production led to the growth of laser welding.

As one of the three most important applications in laser processing, the application of handheld fiber laser welding machine has been widely promoted in recent years, and the handheld welding equipment is known by more and more people. Traditional welding in the early years can meet the needs of welding, but there are many defects in the welding effect, low yield, production efficiency can not keep up, technical welders difficult to recruit and other problems, this is not safe environmental protection, nor efficient, convenient, beautiful traditional welding mode will gradually be replaced by laser welding.

Equipment features:

1. Select the material

Adopt new upgrade process manufacturing, select high quality raw materials, durable.

2. Work efficiently

Sustainable 24 hours work, fast welding speed, high efficiency, immediately improve the production efficiency of 5-10 times.

3, stable performance

Stable operation, easy maintenance, can achieve high efficiency, high precision, high performance welding.

4, solid welding

The welding effect is good, the welding is firm, the weld is beautiful, the deformation is small, the processing range is wide.

5. Simple operation

2 hours operation, hand-held arbitrary Angle welding parts, general operation, no professional welder can also be easily operated.

6, strong scalability

Can connect wire feeder, robot, optional single pendulum or double pendulum welding head.

Configuration advantages:

1, flexible transmission non-contact welding, with greater flexibility, can be welded difficult products.

2, through the optical fiber spot shaping, welding spot energy distribution is uniform, easy to obtain the best molten pool.

3, hand-held welding head adopts unique concept design, hand-held welding head light weight, humanized operation.

4, the box size is small, convenient for other site hand-held welding operations.

5, replacement parts can be cut metal, or metal rust removal of other laser applications.

6, the equipment comes with safety lock, can only trigger the laser on metal, to prevent laser injury.

Product application:

Widely used in cabinet, elevator, frame, oven, door and window guardrail, distribution box, home industry and other complex irregular welding process, perfect replacement of traditional argon arc welding, electric welding in thin stainless steel plate, iron plate, aluminum plate and other metal materials welding.

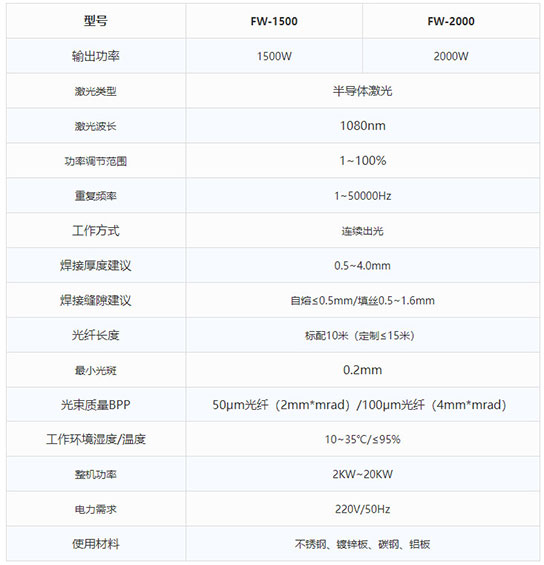

Technical parameters:

Value-added services:

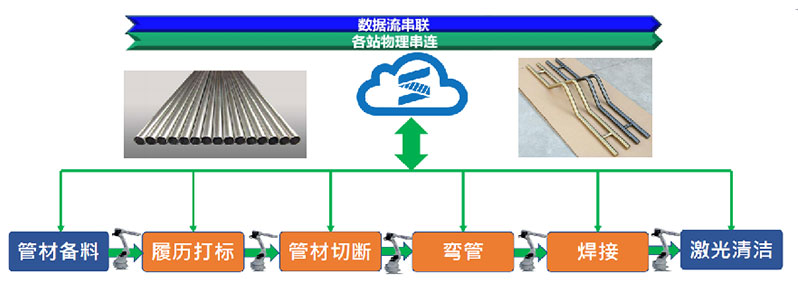

We provide complete solutions for sheet metal industry, steel pipe application, welding processing, cutting, bending and other automation products.