With the continuous improvement of living standards, food quality and safety has become the focus of social concern. Our country as a big population, food industry packaging technology rapidly develops. Products in the production process need to carry out such as production date, production batch and other inkjet operation, in the inkjet process, often because of equipment, personnel, production environment and other factors, such as: leakage, inkjet offset, packaging bag overlap, fuzzy inkjet code, inkjet character missing inkjet code defective products.

Production date is an important standard for us to evaluate food safety. Therefore, it is an important link in the food production process to ensure the correct and clear labeling of production date and other relevant information. How to quickly and accurately detect defective ink-jet products and improve the accuracy and integrity of ink-jet code is an urgent problem for many food manufacturers to solve.

The common characteristics of food production and application are continuous mass production and high requirements for appearance quality. At present, most of this work with high repeatability relies on manual detection, which brings huge labor cost and management cost to the factory, and has low efficiency and low accuracy. The application of machine vision technology to the OCR detection of packaging bag coding has a very broad market demand.

First, test articles

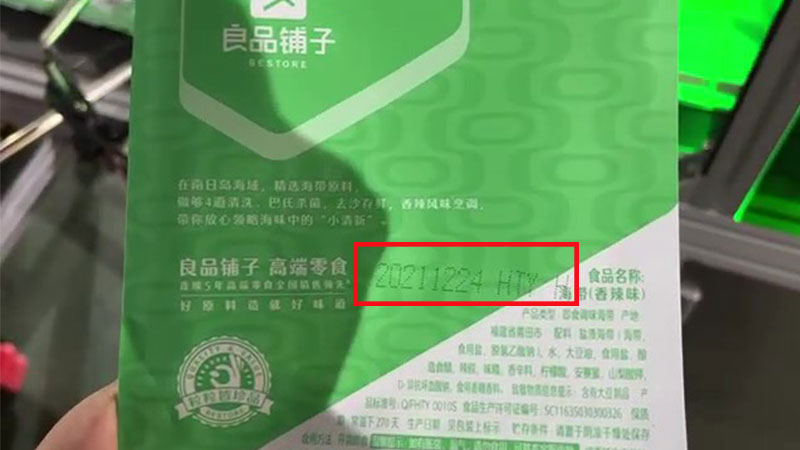

Food packaging bag injet date.

Two, testing requirements

To achieve accurate identification of food packaging date coding, such as missing code, wrong code, skewed code, coding position deviation.

Three, detection difficulties

1. The background color of food packaging bags is different, which is easy to be interfered by the background color, and individual background color bags are easy to reflect;

2, character length, Angle is different;

3. The deviation of coding position is different.

Fourth, the solution

Fuwei intelligent OCR character detection system can confirm, identify and determine the food packaging code characters, so as to perfectly recognize the production date of food production line products.

Five, the work process

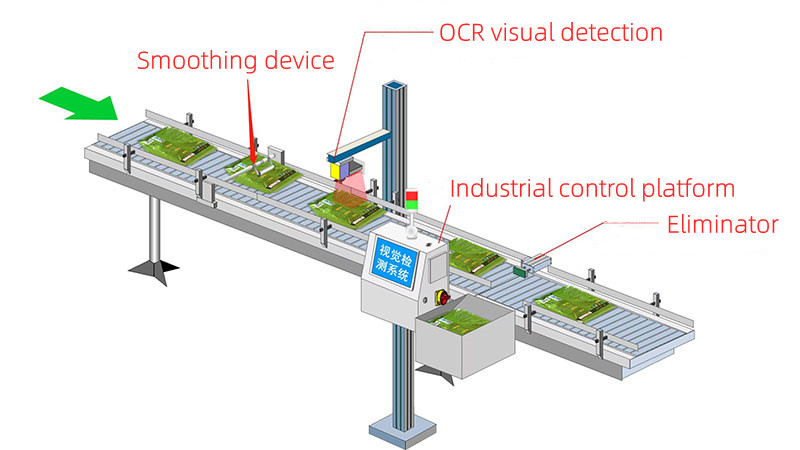

1. Install OCR character visual detection system on food production line;

2. When food packaging bags flow into the visual detection station after coding, the picture of packaging bag is sent to the system by triggering the machine vision sensor. The system extracts and analyzes the picture taken and compares it with the set to know whether the characters of packaging bag coding are missing code, wrong code, crooked code and whether the coding position is offset;

3. When it detects that there are missing code, wrong code, crooked code and offset of coding position, the system sends NG signal to the eliminating device for eliminating processing and warning.

The OCR character detection system is used for packaging bag coding detection, which greatly reduces labor cost, improves production line production efficiency and character recognition accuracy through automation, and helps the food industry to conduct high-quality detection.

Fuwei Intelligent focus on machine vision, intelligent robot, flexible equipment research and development, production and sales, for many packaging industry manufacturers to solve the problem of inkjet character recognition, by the majority of customers and friends praise. In the future, we will continue to adhere to research and development of machine vision product technology and continuous iteration of vision related application products, constantly improve the market competitiveness of products, and accelerate the transformation and upgrading of intelligent manufacturing industry in our country.