In recent years, Chinese manufacturing industry has been improving its intelligence level and stepping forward into high quality development. 'Intelligent manufacturing technology is of great significance for our country to accelerate digitization, networking and intelligentization and promote high-quality development of manufacturing industry, which is conducive to quality reform, efficiency reform and dynamic reform of Chinese manufacturing industry.

Bearing in mind the General Secretary's instructions, Fuwei Intelligent focuses on intelligent robots, continuously promotes industrial intelligent manufacturing, energizes the industry, and develops the energy industry with high quality.

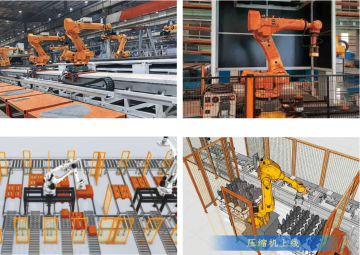

Intelligent robot

Fuwei Intelligent provides visual guidance intelligent grasping standard solutions, adopts self-developed and efficient visual algorithm, provides one-stop visual solutions, hardware and software and peripheral equipment design, with industry-leading disorderly grasping hardware and software system.

Product features:

Multi-scenario, multi-function selection, high intelligence, stability and reliability, rich application cases, high cost performance.

Product advantages:

1. Fuwei Intelligent provides AI+2D/3D vision + robot overall solution, endows intelligence to machines, and realizes flexible manufacturing and digital manufacturing.

2. The visual guidance system provides common robot control, visual positioning, deep learning, collision detection and other functional modules, which can be quickly combined according to the actual application scenarios.

3. Visual recognition and positioning algorithm based on AI deep learning can adapt to various environmental changes in industrial scenes, and the recognition algorithm is more intelligent.

4, can be in various industrial environment stable operation.

5. It has been applied in automobile, new energy, construction machinery, 3C and other fields, and has been highly recognized by customers.

6. The price of the whole package is only about half of the typical similar products abroad.

High precision 3D workpiece unordered grasping

The spark plug and screw are placed in the material frame in disorder. Through 3D visual recognition positioning, the robot is guided to automatically complete the feeding. The orientation of the workpiece can be adjusted to ensure the consistency. Replace labor, reduce cost, improve equipment stability, to achieve automatic production.

Technical difficulties:

1. The workstation is located at the entrance of the workshop, and the light changes greatly in the morning and evening;

2. The state of incoming materials is disorderly, making feeding more difficult;

3. Multiple products are produced at the same time, and automation equipment cannot be adapted.

Technical advantages:

1, can adapt to the drastic change of environmental light, instead of artificial;

2. Object detection and positioning algorithm based on deep learning, obstacle avoidance and trajectory planning algorithm of intelligent robot arm;

3. It can adapt to the scene of simultaneous production of multiple workpieces.

3D visual guide welding parts loading

The welding parts are placed in the material frame out of order, and the 3D vision identifies and positions the workpiece to realize the disorderly grasp and feeding of the welding parts. The robot arm replaces the manual, the grasp accuracy is less than 0.2mm, and can run stably for 24 hours.

Technical difficulties:

1. The placing accuracy shall be less than 0.2mm;

2. The state of incoming materials is disorderly, making feeding more difficult;

3. High tempo requirements.

Technical advantages:

1, the use of 3D+2D solution, workpiece positioning accuracy is less than 0.2mm;

2. Use deep learning and hardware acceleration algorithm to improve the tempo;

3. It can adapt to the scene of simultaneous production of multiple workpieces.

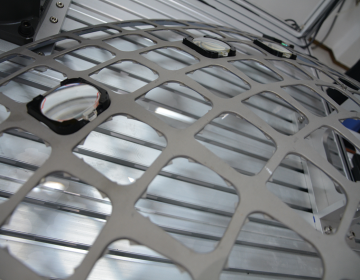

High precision 3D visual guide lens coating automatic feeding

3D vision can locate the position of the glasses umbrella frame with high precision, realize the grab and placement of the lens, replace manual with automation, and can run stably for 24 hours.

Technical difficulties:

1. The placing accuracy shall be less than 0.1mm;

2, the umbrella frame is ellipsoid shape, visual positioning is more difficult;

3. Part of the umbrella stand is deformed, resulting in inaccurate placement.

Technical advantages:

1. Adopt self-developed high-precision 3D visual positioning algorithm, positioning accuracy is less than 0.1mm;

2. Self-developed workpiece model building algorithm is adopted to realize the adaptive adjustment of photo points;

3, can adapt to the scene of multiple umbrella stand production at the same time.

As one of the important parts of intelligent robot, machine vision plays a decisive role in improving the flexibility and maneuverability of robot. It can be predicted that with the deep integration of machine vision and robot, intelligent robot will occupy an important place in the field of intelligent equipment in the next ten years.