As the main bearing component of the power battery of new energy vehicles, the battery tray can effectively withstand the impact of the external environment, and has extremely high requirements for its bearing capacity and assemblability.

The rapid development of new energy vehicles has led to the wide application of battery tray detection technology. Battery tray is an important auxiliary equipment in the production process of new energy vehicle battery. The quality of battery tray directly affects the quality and performance of battery. Therefore, the accuracy and reliability of battery tray detection technology is very important.

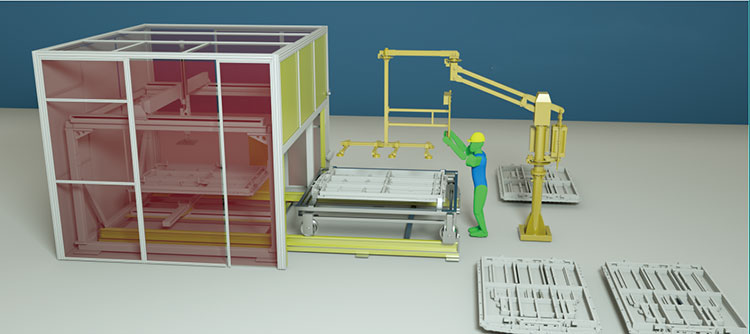

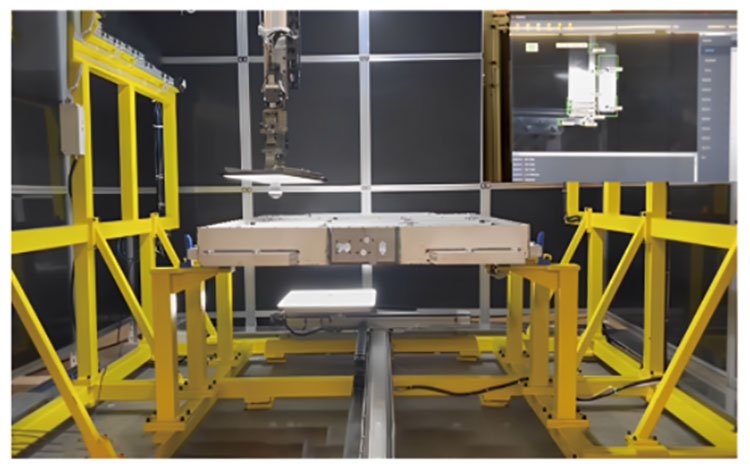

In order to ensure the quality of new energy vehicle battery tray, Fuwei Intelligent has been exploring new energy vehicle battery tray detection equipment for many years, forming a new energy vehicle battery tray detection solution. Robot + machine vision is adopted to detect the defects of battery tray instead of manual, which completely solves the problems of missing detection and wrong detection in manual detection. The equipment has high detection accuracy and fast efficiency.

Test contents:

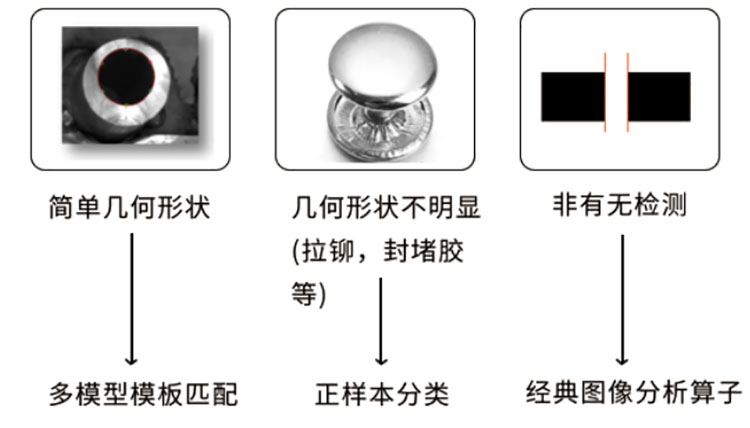

1. Whether the positive face position is detected and size measured;

2. There is no detection, size measurement, color difference detection of reverse face position;

3.hole location and size, location, explosion-proof valve installation hole and size;

4. there is no leakage welding detection;

5.plugging glue detection;

6. Detection of end mounting holes.

Device function:

1. Assist mechanical arm to assist loading and unloading, reduce manual handling fatigue;

2.fixture quick change device, change the product model can be quickly;

3. Real-time display of detection interface, real-time display of detection status of different points;

4. Data analysis function, customize and select detection time nodes, flexibly extract detection and analysis reports;

5. can be connected with engineering MES system, to achieve quality traceability.

The new energy vehicle battery tray detection equipment can effectively improve the detection level and quality of the battery tray. Compared with the traditional detection method, the detection speed is increased tens of times while freeing the labor force, which perfectly matches the production beat demand of the automatic production line. By means of high-precision and high-accuracy measurement, defects of battery trays are found and dealt with in time, which saves tens of millions of inspection costs and repair costs for the factory every year, and prevents losses and safety risks caused by poor product processing and flow to the market.

Battery tray detection technology has a very important position in the field of new energy vehicles, which is one of the important safeguard measures to ensure the quality and safety of new energy vehicles. The continuous development and innovation of new energy vehicle battery tray detection technology will provide more reliable, efficient and intelligent guarantee for the development of new energy vehicle industry. We have reason to believe that with the continuous improvement of battery tray detection technology, the future of the new energy automobile industry will be better.