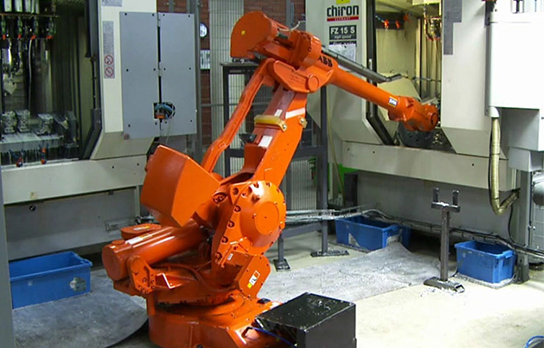

Automatic loading and unloading robot is a kind of robot system which can realize automatic loading and unloading of materials. Through the use of automation technology and equipment, it can autonomously complete the task of material loading and unloading without manual intervention.

Automatic loading and unloading robots usually have the following features and functions:

1. Autonomous operation:

The automatic loading and unloading robot can independently load and unload materials through its own intelligent control system. It can sense and analyze the working environment, make corresponding decisions, and complete tasks.

2. Grasping and holding ability:

The robot is equipped with a flexible and reliable grasping device that can accurately grasp and hold different materials according to their shape, size and weight. The grasping device can be a manipulator, claw, suction cup and other forms.

3. Navigation and positioning system:

Through the use of navigation and positioning systems, the robot is able to accurately sense the location of materials and determine the target location for loading and unloading. This is often done using sensors, vision systems, laser scanning and other technologies.

4. High precision motion control:

The robot has highly accurate motion control to achieve the required movement, rotation and positioning. It can move according to the programmed instructions in accordance with the set trajectory to ensure the safe handling and placement of materials.

5. Programming and control:

Automatic loading and unloading robots can be programmed to perform specific tasks. You can use programming languages or graphical programming tools to guide the movement and operation of the robot. Through programming and control, the robot can adapt to different production needs and be flexibly adjusted and optimized.

Automatic loading and unloading robots play a key role in industrial production, they can improve production efficiency, reduce labor costs, improve product quality and consistency, and can work in different working environments and conditions to adapt to the loading and unloading needs of various materials.