In the field of intelligent manufacturing, visual loading and unloading technology, as an important technical means, is gradually being widely used and concerned. The introduction of visual loading and unloading technology has brought more efficient, more accurate and more intelligent production methods to the manufacturing industry, and promoted the manufacturing industry to a higher level.

Visual loading and unloading technology is the use of computer vision and image processing technology to realize the automatic detection, identification and positioning of materials, and to achieve the accurate placement of materials. Through cameras and sensors and other devices, the system can obtain and analyze the visual information of the material, so as to achieve the control and operation of the material.

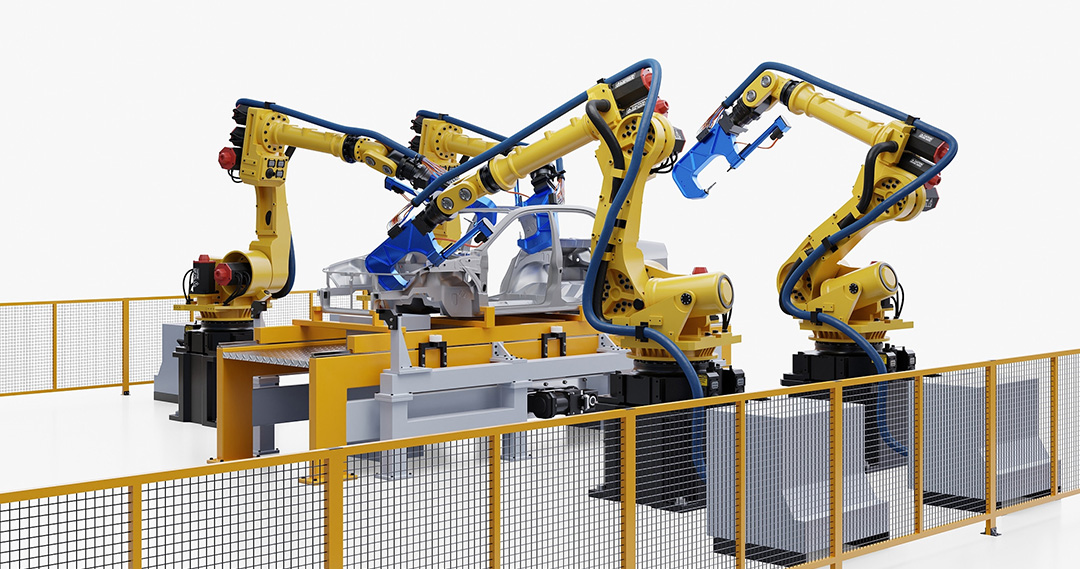

The technology has a wide range of applications. In the automotive industry, visual loading and unloading technology can accurately identify the type, position and direction of parts on the assembly line, and accurately position and place them in the corresponding position, greatly improving the efficiency and accuracy of assembly. In the electronics manufacturing industry, visual loading and unloading technology is able to identify and locate electronic components to ensure that they are accurately placed on the circuit board, improving the quality and production efficiency of electronic products.

The advantages of visual loading and unloading technology are not only reflected in the high efficiency and accuracy, but also in its intelligent characteristics. Through the introduction of artificial intelligence and machine learning algorithms, the visual loading and unloading system can continuously learn and optimize, and continuously improve the identification and positioning ability of materials in practice. At the same time, the visual loading and unloading system can automatically adjust the attitude and position to adapt to different shapes and sizes of materials, improving the flexibility of the system.

The application of visual loading and unloading technology has brought significant improvements in manufacturing productivity and reliability. With automated material identification and location, manual time is reduced and the risk of operational error is reduced. At the same time, the introduction of visual loading and unloading technology also reduces labor costs and provides a safer working environment.

With the continuous development and innovation of technology, visual loading and unloading technology will continue to be promoted and applied. In the future, visual loading and unloading technology is expected to achieve higher precision, faster and smarter operation, further promote the development of intelligent manufacturing, and bring greater production efficiency and competitive advantage to manufacturing enterprises. Let's look forward to visual loading and unloading technology playing a more important role in smart manufacturing and promoting manufacturing toward a more efficient and accurate future.