In industrial production, loading and unloading is a very important process, can be directly related to the efficiency of the whole production line. In the environment of increasing social production efficiency, it is difficult for traditional manual to keep up with the work of rapid mass production. At the same time, a lot of manpower is consumed, and the loading and unloading robot can automatically carry out the feeding and unloading work.

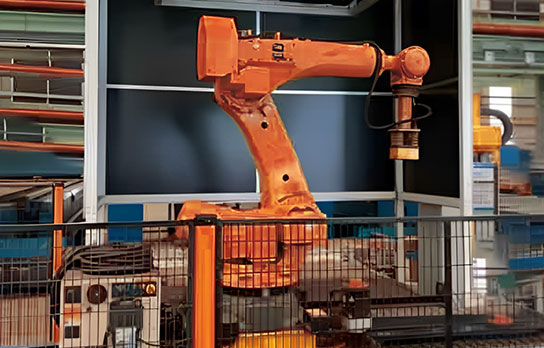

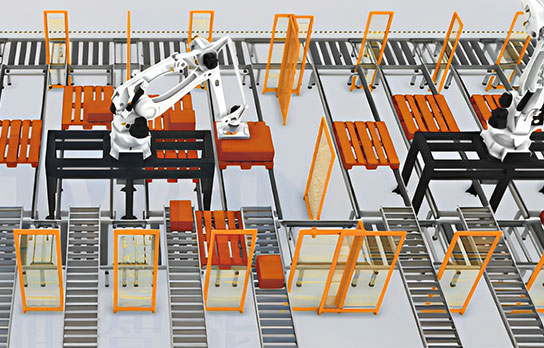

More and more manufacturers begin to use loading and unloading robots to replace manual work, which can effectively replace manual work and complete production requirements in quality and quantity. Automatic loading and unloading robot, 3D vision combined with industrial robots, visual guidance robot from the material frame grab products, placed on the feeding line, widely used in automobile, construction machinery, steel and other fields of the workpiece feeding link.

Automatic loading and unloading robot occupies an important position in the industrial field, so what are its advantages?

1. High production efficiency

In order to improve production efficiency, it is necessary to control the production tempo. In addition to the fixed production and processing beat can not be improved, automatic loading and unloading robot instead of manual operation, so that you can well control the beat, avoid the impact of human factors on the production beat, greatly improve the production efficiency.

2. Flexible process modification

We can change the production process quickly by modifying the program, and the debugging speed is fast, which saves the time of training for the labor, and can be put into production quickly.

3, improve the quality of the workpiece factory

Loading and unloading robot automatic production line, from the feeding, clamping, feeding are completed by the robot, reduce the intermediate link, parts quality is greatly improved, especially the workpiece surface is more beautiful.

4. Simple application

Automatic loading and unloading robot, in the application only need to carry out automatic modification of the original machine tool can be realized, there is no need to buy a new CNC lathe and change the structure of the lathe, so the application is simple.

Using automatic loading and unloading robot instead of manual, automatic completion of loading and unloading and other automatic operations, can save labor costs for enterprises, to achieve high-speed, efficient, high-quality automated production. Under industry 4.0, the normalized scene of many smart factories cannot be separated from the key technical guidance of 3D vision. In the future, 3D vision will appear in more new application scenarios, and gradually break through the industrial detection scene, and gradually expand to the field of intelligent life.