In recent years, the global machine vision market is in rapid development, industrial control and industrial automation technology is developing rapidly, 3D machine vision is more and more applied to industrial production. Behind the high-speed production is the stable name that guides the grab, and the error-free grab brings the improvement of the efficiency of the entire production line.

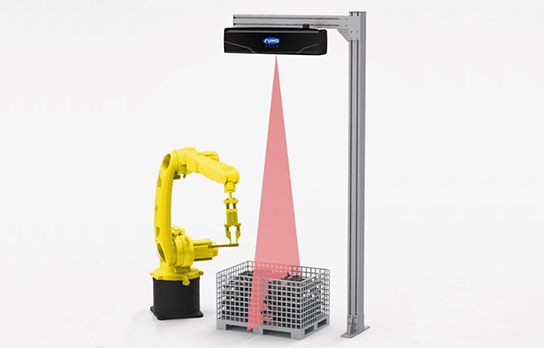

Robot vision is the 'eyes and brain' of robot, which is mainly composed of industrial camera, light source, industrial computer and corresponding image analysis software system. The perfect combination of 3D machine vision and motion control infuses a 'vitality' into the upgrading of industrial robot industry.

What is robot visual guidance?

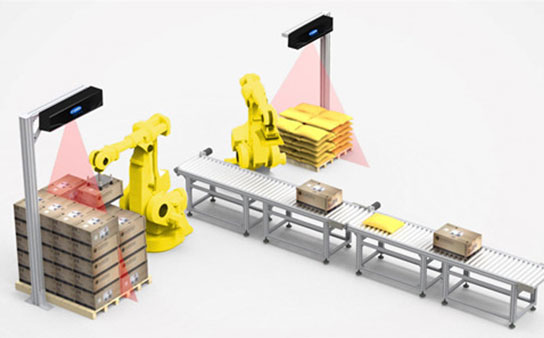

Robot visual guidance is the use of machine vision to report the position and direction of components. In the automated production line, the machine vision system is used to understand the changes of the robot in the operation process and the working environment in real time, and make corresponding adjustments to ensure the correct completion of the task.

Robot visual positioning requires that the machine vision system can quickly and accurately find the parts under test and confirm their position. Machine vision is used to locate and guide the mechanical arm to grasp accurately.

Robot visual guidance will be widely used in the field of industrial robots, and has four main functions.

1. Guidance and positioning

Visual positioning requires machine vision system to quickly and accurately locate and position the parts under test. Machine vision is used to identify loading and unloading material and guide the robot arm to grasp it accurately. In semiconductor packaging, the device needs to adjust the pickup head based on the chip position information obtained through machine vision to accurately pick up and bind the chip. This is a more basic application of visual positioning in the machine vision industry.

2. Appearance detection

Inspect the production line for quality problems. This link is also the replacement link for most of the work. In the medical field related to machine vision, the main detection is size detection, bottle appearance defect detection, bottle shoulder defect detection and bottle mouth detection.

3, high precision detection

The accuracy of some products is as high as 0.01-0.02m or u level, which cannot be detected by human eyes and must be completed by machines.

4. Identification

Uses machine vision to process, analyze, and understand images to recognize different patterns of objects and objects. Data can be tracked and collected, and used widely for automotive parts, food, pharmaceuticals, and more.

In order for robots to be capable of more complex tasks, they not only need better control systems, but also need to be more aware of changes in the environment. Robot vision has become the most important robot perception function because of its large amount of information and complete information. It is particularly good at 3D visual guidance, making it the most advanced visual guidance product in the industry and able to cover a wider range of robot applications.

It turns out that robot visual guidance mainly solves the localization problem. High open source, high reliability, and high ease of use have become the basic requirements for related automation products. The development of robot visual guidance technology, the realization of robot autonomous navigation, as well as the integration with big data and intelligent control system, leads the new trend of industry development, enabling industrial automation technology change.