Sheet metal is a comprehensive cold working process for sheet metal, including cutting, punching/cutting/compounding, folding, welding, riveting, splicing, forming, etc. Its remarkable feature is the same thickness of the same parts. The products processed by the sheet metal process are called sheet metal parts.

The existing technical solution has the following defects: Each processing time of stamping cutting processing, tapping processing, turning processing and bending processing is not the same. In general, the required time of stamping cutting processing of a single sheet metal part is longer than the required time of tapping processing of a single sheet metal part, which is easy to cause excessive accumulation of sheet metal parts on the conveyor belt. If you do not want this to happen, It can only reduce the speed of stamping cutting or increase the placement time of sheet metal parts on the conveyor belt, which leads to low processing efficiency.

In view of the shortcomings of the existing technology, Fuwei intelligent launched the sheet metal parts high-speed production line.

High-speed production line of sheet metal parts

The flexible production line with intelligent, high-speed and comprehensive functions of sheet metal parts can realize fully automatic production.

Production line process:

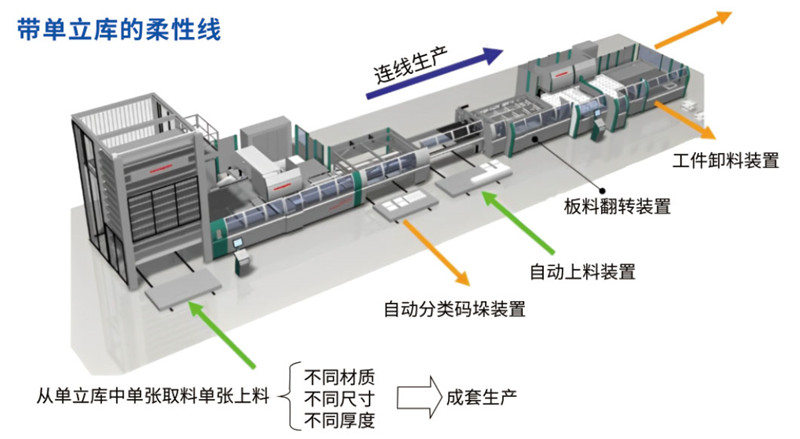

According to the production order information, automatically from the metal raw material library fork plate, and according to the required shape in the stamping center for processing. After processing, the products are transported to the bending center through the turning platform for bending and forming, riveting and riveting, and nut pulling and riveting. Then the reinforcement bars are automatically riveted and fixed, and then transported to the automatic assembly system for installation. After installation, the products are packaged and labeled.

With the popularization and promotion of intelligent manufacturing and industry 4.0, the industry and customers have increasingly high requirements for intelligent factories and automated production lines. Now it has become a basic option to require new factories and new equipment to have digital and information capabilities, and the processing and manufacturing of sheet metal parts has also developed in the direction of intelligence. In order to ensure that the surface forming of sheet metal meets the requirements, surface quality and internal quality must be ensured.

The high-speed production line scheme of sheet metal parts can greatly improve the automation level of sheet metal processing industry and help manufacturing enterprises realize high-quality automatic and intelligent production. Highly automated sheet metal flexible production line processing process, set automation, intelligent in one. With the task allocation, stamping automatic loading and unloading, bending center automatic bending forming, automatic riveting fixed installation, automatic assembly and other powerful functions, truly realize automatic production.