In the era of Industry 4.0, industrial robots are widely used in smart factories to replace manual automation operations, such as automatic loading and unloading. This automatic production method can save labor costs for enterprises, and achieve high-speed, efficient and high-quality production. In order to achieve this normalized scene, 3D vision technology has become a key guiding technology.

Nowadays, 3D visual guidance is more and more widely used in the field of automobile manufacturing. As a high-tech enterprise in domestic high-end flexible equipment manufacturing, Fuwei Intelligent combines machine vision and AI algorithm to provide a perfect solution for the metal parts loading and unloading production line, which can replace manual operation, automatically complete the production task, and realize the automation of industrial feeding. At the same time, the technology is suitable for a variety of industries, including automotive, construction machinery, steel and other fields of workpiece feeding links, to meet the needs of various metal parts feeding and other scenarios.

Project background:

With the development of the manufacturing industry, labor costs continue to increase, and the transformation and upgrading of automation and intelligence have become an urgent problem for the manufacturing industry to solve. Especially in the metal parts loading and unloading scene, there are many problems in the traditional manual handling, manual handling efficiency is low, the production cost is high, can not meet the requirements of efficient production. In addition, the pace of manual loading and unloading is slow, which cannot meet the high tempo requirements of automatic processing, and it is also easy to lead to safety accidents. In order to solve these problems, the manufacturing industry urgently needs to introduce automation and intelligent technology to complete the loading and unloading work.

Technical difficulties:

1. The workpiece is a smooth hollow metal piece, which is difficult to grasp;

2. High accuracy requirements, placing accuracy requirements less than 0.2mm;

3. The incoming materials are in disordered state and need to be positioned twice.

Solution:

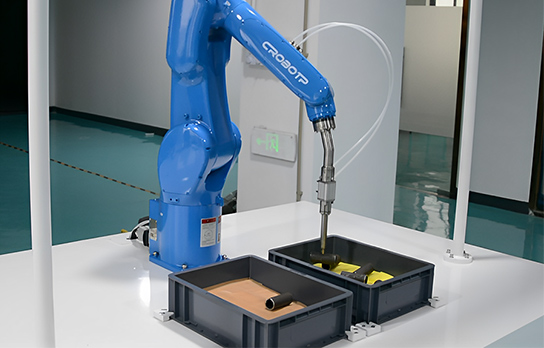

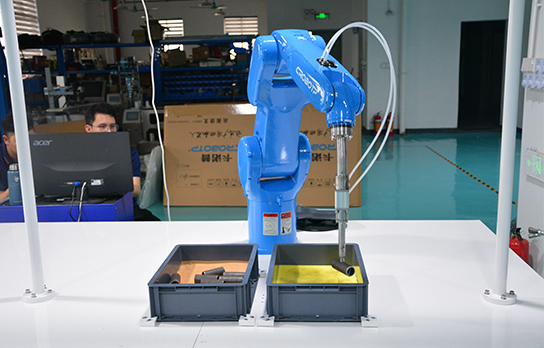

In response to the complex environment and high labor costs in manufacturing factories, Fuwei Intelligent provides 3D vision guided robots to achieve automatic loading and unloading solutions. This scheme guides the industrial robot to accurately identify the workpiece in the turnover basket, and feedbacks the information in real time to guide the robot arm to grab it in disorder and place it correctly to the loading position. The entire process achieves high efficiency with a single beat time of 6 seconds, thus automating the entire feeding operation. This solution not only increases productivity and reduces costs, but also significantly improves accuracy and safety.

Technical advantages:

1. Using self-developed high-precision 3D visual positioning algorithm, fast collision detection algorithm and intelligent robot arm trajectory planning algorithm, the grasping success rate is as high as 99%;

2. Replace labor, improve production efficiency, and meet the needs of various metal parts loading and other scenarios;

3. It can run stably for 24 hours to achieve high-speed, efficient and high-quality automated production.

With the rapid development of industrial automation, the mature application of machine vision technology has been widely concerned, and has shown great development potential in the field of intelligent manufacturing. In the future, we will see more intelligent application scenarios emerge, bringing more convenience and benefits to people's lives and production. Machine vision will become an important support for intelligent manufacturing and intelligent life, and promote social progress and economic development.