In traditional industrial production lines, the grasping and feeding operations of small items such as spark plugs and screws usually require manual operation, which has some challenges and limitations for large-scale and efficient production. Manual grabbing and loading require a lot of manpower input, time and resources. In high volume and continuous operation of production lines, manpower is difficult to meet the demand. Operator errors in grasping and placing may result from fatigue, inconcentration, or inexperience, affecting productivity and product quality. In the high-speed production process, manual operation is difficult to ensure the accuracy and consistency of high-speed grasping and placing actions.

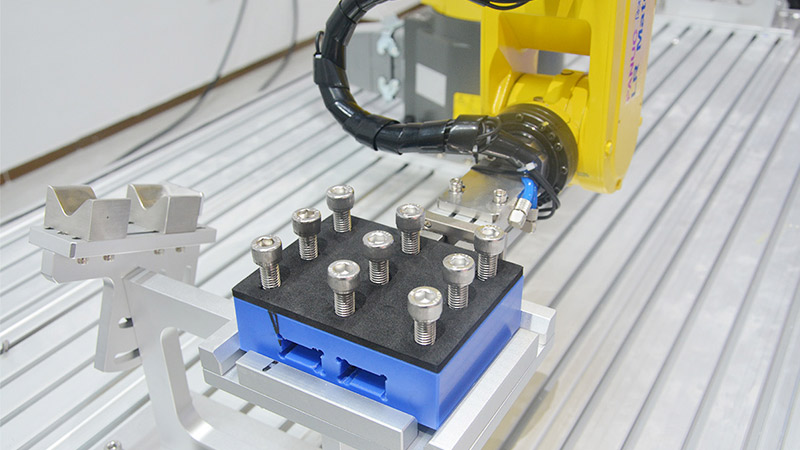

The application of Fuwei intelligent 3D vision guide spark plug and screw disordered grab feeding, through 3D visual recognition positioning, guide the robot to automatically complete the feeding, you can adjust the orientation of the workpiece to ensure consistency. Instead of labor, reduce costs, improve equipment stability, to achieve automated production.

Case background:

Spark plugs and screws are placed in the material frame in disorder, through manual packaging selection, according to the front and back of the workpiece to confirm whether it needs to be turned over, completely by manual, workers labor intensity, high cost, so the need for automatic transformation.

Technical difficulties:

1. The workstation is located at the entrance of the plant, and the light changes greatly in the morning and evening;

2. The incoming materials are in disorder, making it difficult to feed;

3. Multiple products are produced at the same time, and automation equipment cannot be adapted.

Solution:

1. The visual part adopts 3D structured light camera + deep learning algorithm;

2. Use 3D vision to locate products in the material frame to avoid collision points and generate grab points;

3. Use 2D vision for 2 times accurate positioning to ensure the accuracy of feeding;

4. Set multiple grab points for the workpiece to improve the frame clearing rate.

Technical advantages:

1, can adapt to the drastic changes in environmental light, instead of artificial;

2. Target detection and positioning algorithm based on deep learning, obstacle avoidance and trajectory planning algorithm of intelligent robot arm;

3. It can adapt to the scene of simultaneous production of multiple workpieces.

The application of 3D visual guide spark plug and screw disorderly grab feeding can make the production process more efficient, flexible and reliable, improve the level of automation of the production line, reduce manual errors and labor costs, and create greater value and competitive advantage for the production enterprise.

Fuwei intelligent AI+3D vision guide workpiece loading and unloading solution technology is mature, easy to use, widely used in automotive, construction machinery and other industries, can solve a series of complex problems in the workpiece loading and unloading scene, such as workpiece reflection, dark color, complex structure and out-of-order stacking. After years of on-site practice, has accumulated a large number of workpiece loading and unloading application experience, has passed many domestic large-scale project terminal verification, to help many enterprises to achieve a higher level of automation, flexible production.