With the rapid development of the automobile industry, the demand for auto parts is also increasing. In the process of auto parts production, the material feeding link of auto parts production line has always been a tedious and error-prone link.

The traditional manual grab loading method has some problems such as low efficiency, high production cost and low safety of production line. In order to solve this problem, the introduction of visual guidance technology can effectively improve the automation level and production efficiency of auto parts production lines.

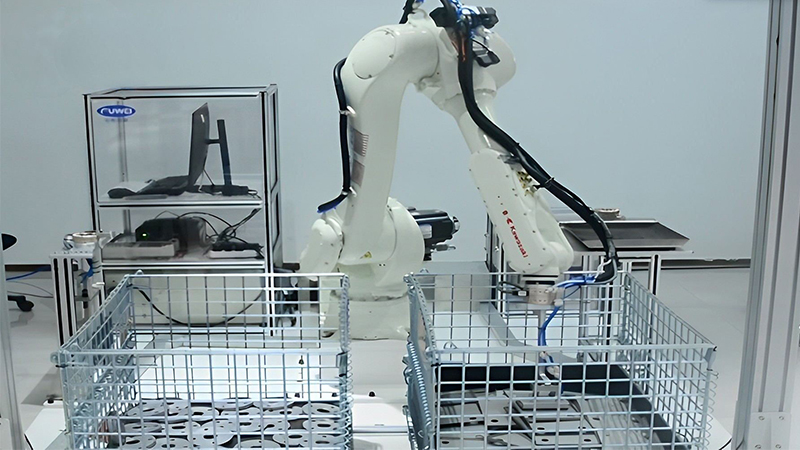

The visual guide robot grabs the auto parts from the deep frame and places them on the feeding conveyor line, which can be applied to the workpiece feeding link in the fields of automobile, construction machinery, steel and so on.

Case background:

Small metal parts need to be placed in a designated position so that the next assembly process connects different semi-finished parts through a screw. The traditional processing method is manual sorting of sheet metal parts, and the repetitive action and working time of sorting are easy to cause defective products and industrial accidents. A set of automatic picking equipment is designed to meet the needs of this application.

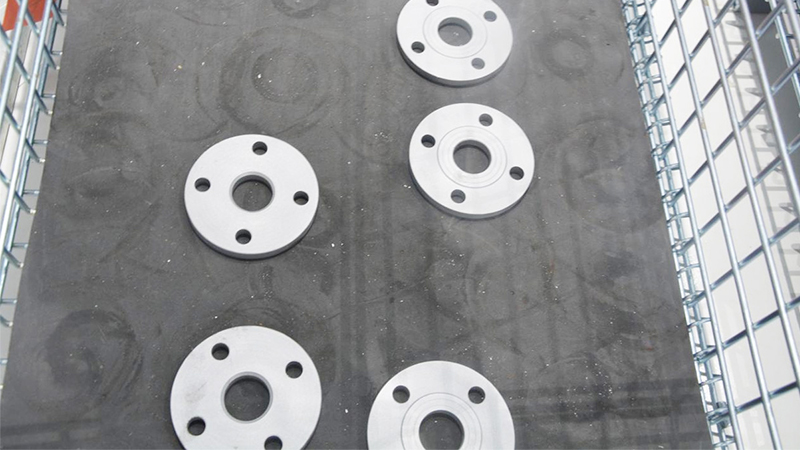

Workpieces - sheet metal parts

Technical difficulties:

1. The factory environment is complex and the light changes greatly;

2. The workpiece can not be loaded with standard equipment;

3. Need to quickly compatible with multiple products, traditional non-standard automation equipment can not achieve.

Work-piece flange

Solution:

1. The visual part adopts 3D structured light camera + deep learning algorithm;

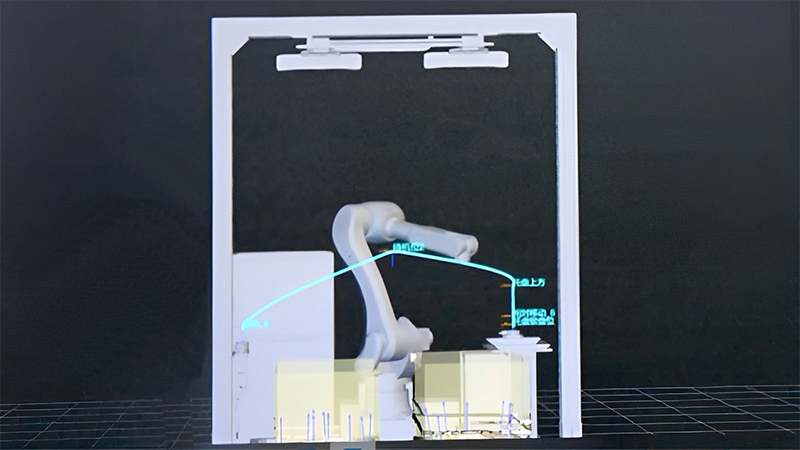

2. Use 3D vision to locate products in the material frame to avoid collision points and generate grab points;

3. Use 2D vision for 2 times accurate positioning to ensure the accuracy of feeding;

4. Set multiple grab points for the workpiece to improve the frame clearing rate.

3D grasp simulation

Fuwei intelligent AI+3D visual guide workpiece loading and unloading solution is mature and easy to use, which can greatly improve the accuracy and efficiency of auto parts feeding, and improve the level of customer production line automation and flexibility. Based on the actual scenario needs of customers, Fuwei Intelligent will provide powerful, flexible and easy-to-use AI+3D vision solutions to help the intelligent transformation and development of the auto parts industry.